LA115-A5-11HT High Quality 1NO+1NC Maintained Extended Push Button With Round Head And Without Illumination

AL70-RYG-31C5 Warning Light Tower Red Yellow Green LED Signal Tower Light Alarm Lamp Tower

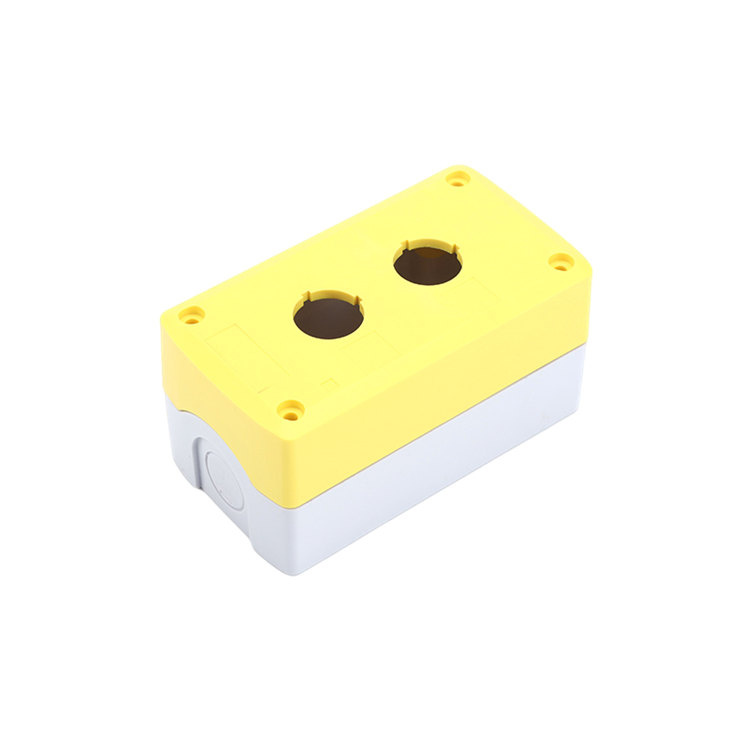

GOB-2A-YW High Quality Two Holes Yellow Cover White Base Push Button Control Box

GL-25F11S/R23-SJ Metal push button

CJX2-0912(LC1-D) Ac Electric magnetic contactor

AD116-22DS High Quality Φ22 LED Indicator Light With Black Shell And Yellow Light

CJX2-25(LC1-D) AC Electric magnetic contactor

GXB4-EK3461 Red selector switch with LED light push button switch

GXB2-ES142 1NC Key Control Emergency Stop Push Button Switch With Red Mushroom Shape Head And Rotating Reset

GXB2-EC42 Emergency stop and shutdown mushroom push button switch with red pusher push pull

CJX2-(LC1-DN)95 ac Electric magnetic contactor

LA115-5-BD Green Flush Push Button Switch Momentary Round Head With Symbols And Light